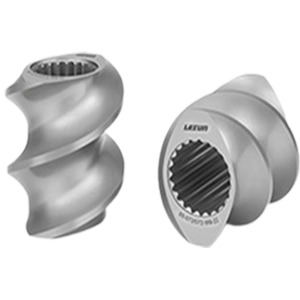

Technical Details of Two-fighted Screw Elements

Model:Φ18mm~φ400mm

Material:N00/W6/HIP

Properties: Wear-resisting, Corrode-resisting and Durable

The materials for selection and the heat treatment

△ The nitrided steel, N00 72h two-stage gas nitriding);

△ The high-speed tool steel, W6 (vacuum quenching);

△ The die steel, D2(1.2379, SKD11,K110) (quenching + tempering);

△ The bimetal composite rods (inside tough, outside hard or corrosion resistant), supplied by SAAR company from German or HTM company from Swiss;

△ Other special materials such as Hastelloy, W-C, nickel-based alloy, etc.

Two-fighted Screw Elements Function

1. Excellent material performance

2. Short and limited residence time

3. Good self-wiping