Extrusion is crucial in manufacturing, where screws and barrels play pivotal roles. However, wear and tear in

extruder screw elements can significantly impact efficiency and lifespan. Let's explore the main factors contributing to wear in these critical components.

Abrasion:

One of the primary causes of wear in extruder screw elements is abrasion. Friction and pressure within the extruder barrel create an environment where abrasive wear thrives. Hard particles such as glass fibers, calcium carbonate, and flame retardants in the polymer gradually erode the surfaces of the screw and barrel. This abrasive effect intensifies at high pressures and temperatures. Surface hardening techniques like nitriding and chrome plating can enhance screw element durability against abrasion.

Corrosion:

Corrosive wear results from chemical attacks by additives and degraded polymer particles, which can chemically corrode extruder components. Exposure to corrosive materials or high temperatures can lead to corrosion and pitting on extrusion screw elements. Corrosive wear is particularly common in the metering zone, where elevated temperatures and prolonged material residence times increase the risk of product degradation. Surface treatments are effective in mitigating the effects of corrosive wear.

These factors highlight the importance of selecting appropriate materials and employing protective surface treatments to enhance the durability and performance of

extruder screw elements. Understanding these causes of wear is essential for implementing preventive measures and maintaining optimal extrusion processes.

Overheating in Extruder Screw Elements:

Excessive heat generated during extrusion can induce thermal degradation, directly causing wear on screw elements. Uneven heating of the cylinder exacerbates this issue, underscoring the importance of maintaining consistent temperature profiles. Implementing effective insulation and cooling systems helps regulate temperatures, reducing the risk of thermal wear and enhancing the extrusion system's overall performance and longevity.

Fatigue in Extruder Screw Elements:

Repeated stress and pressure cycles over time can lead to fatigue wear, gradually weakening

extruder screw elements. This cumulative damage can compromise the screw's structural integrity, potentially resulting in failure.

To mitigate fatigue wear, ensuring proper alignment of the screw within the cylinder is essential. Regular maintenance and inspections are crucial for detecting early signs of fatigue, enabling timely interventions to prevent catastrophic failures.

Other Contributing Factors to Extruder Screw Elements Wear:

Cold Starts: Abrupt starting of the extruder can contribute to wear.

Improper Material Processing: Using corrosive polymers with unsuitable screws can cause wear.

Inconsistent Heating: Uneven heating of the cylinder contributes to wear.

Non-Straight Screws: Lack of straightness in the screw can lead to wear.

Incorrect Materials: Using inappropriate materials for the screw and cylinder can also contribute to wear.

How to Identify the Need for Extrusion Screw Replacement:

Recognizing signs of extrusion screw wear is crucial to maintaining optimal performance and preventing irreversible damage to both the extruder and processed polymer. Key indicators and assessment methods for determining the need for replacement include:

-

Reduced Processing Capacity: Monitoring extruder output for consistent declines below expected levels.

-

Wear on Screw Threads: Examining widening gaps between screw thread crests and cylinder surfaces due to wear.

-

Material Leakage: Noticing material escaping above screw threads indicates wear-related gaps affecting overall output.

-

Elevated Polymer Temperatures: Regularly monitoring temperature profiles for sustained increases indicative of wear-related degradation.

-

Changes in Polymer Characteristics: Observing alterations in appearance or properties such as yellowing or carbon residues, signaling potential thermal degradation.

Identifying these signs early enables timely replacement of extrusion screws, ensuring continued efficiency and product quality in extrusion processes.

Decreased Processing Capacity:

Monitor extruder output; consistent flow rate declines below expectations suggest potential wear.

Screw Thread Wear:

Widening gap between screw thread crest and cylinder surface due to wear may necessitate replacement.

Material Leakage:

Noticeable material escape above screw threads indicates wear-related gaps affecting overall output.

Elevated Polymer Temperatures:

Regularly monitor temperature profiles; sustained rise suggests wear-related degradation impacting polymer properties.

Polymer Characteristics:

Observe changes in appearance and quality; noticeable decline signals potential wear-related degradation, such as yellowing or carbon residues.

Unusual Noise or Vibration:

Increased noise or vibration indicates potential mechanical issues due to wear, requiring investigation and possible replacement.

Higher Energy Consumption:

Significant increase in energy usage indicates reduced efficiency from worn screw elements, prompting closer inspection and potential replacement.

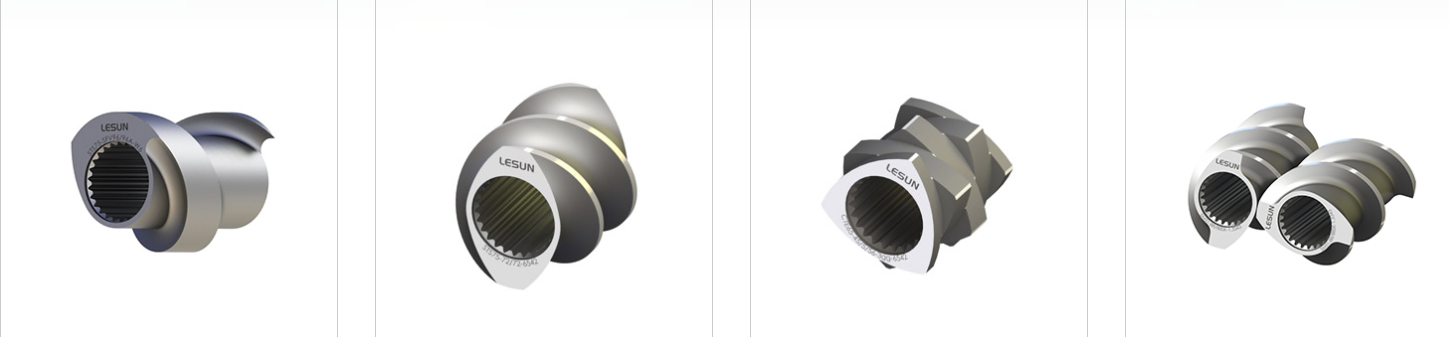

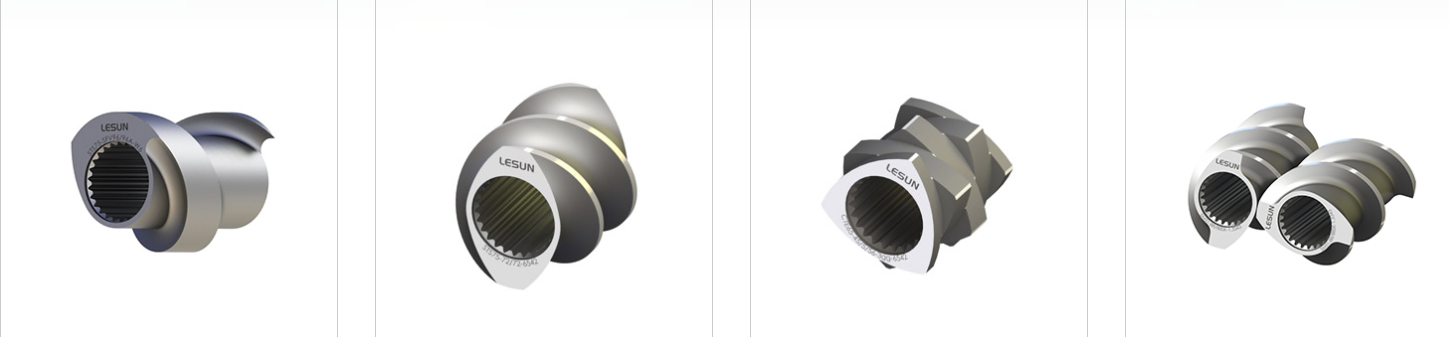

About Us – Manufacturer of Extruder Screw Elements

Nanjing Lesun Screw Co., Ltd. boasts over two decades of experience as a leading industry player. Specializing in the design, production, and after-sales service of twin screw extruders, our focus centers on meticulous research, development, and manufacturing of parallel twin-screw extruders and premium accessories. We are renowned for our high-wear-resistant and anticorrosive thread components, committed to delivering tailored solutions that meet our clients' specific needs.

Our diverse product portfolio features cutting-edge offerings such as twin-screw pelletizers, underwater pelletizers, barrels, screw elements, core shafts, and high-speed side feeders, alongside other essential accessories. As a key supplier of spare parts to top domestic machinery manufacturers, we ensure seamless support for their operations. Moreover, our products reach global markets including Germany, Japan, South Korea, India, Brazil, Taiwan, Singapore, and beyond.

At Nanjing Lesun Screw, we take pride in our dedication to technological excellence and our proactive approach in tackling our customers’ technical challenges. Our customer-centric philosophy allows us to deliver unmatched solutions, fostering enduring partnerships and solidifying our reputation as a trusted leader in the twin-screw extruder industry.